Labeling Machine | OPP Labeling Machine | Sleeve Labeling Machine | Adhesive Labeling Machine | Sticker Labeling Machine.

You are here: Home » Products »

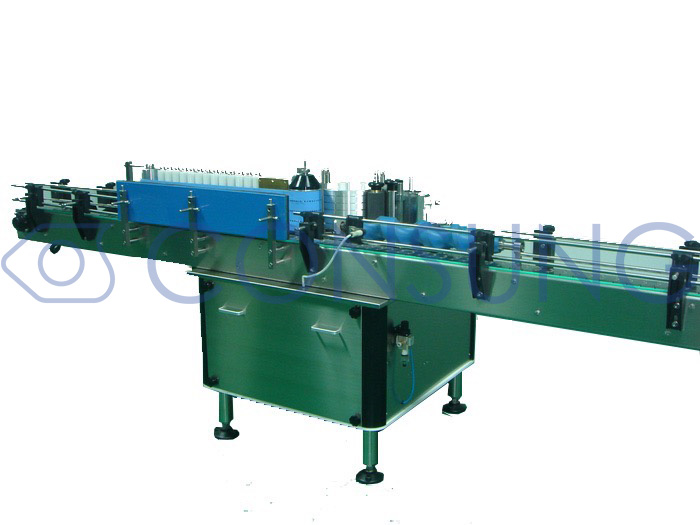

Cold Glue Labeling Machine

» Wet Glue Labeling Machine

» Wet Glue Labeling Machine

Products Catagories

News & Events

-

How to use Germany Sausages ...

[2021/7/27 16:12:58]Adhesive sticker labeling machine can work for sausages food, pet food, plastic tube,oral bottle. ...

-

Received the payment of Duba...

[2021/7/22 11:37:56]The deposit payment of flat conveyor and lifting conveyor, conveyors can connect with filling machine, capping machine,labeling machine and packing m...

-

Dental cream teeth cream tub...

[2021/7/13 15:49:35]Sticker labeling machine work with cans tubes round bottles....

-

New model power cord cable w...

[2021/7/8 9:06:52]Full automatic manual flag labeling machine can paste stick labels on powder cord, electrical cable and wire....

-

Suction cap automatic feedin...

[2021/7/7 9:10:34]The O and U shape labels machine equipment production line from automatic feeding cap, stick labeling to collecting machine work for Medicine indus...

Contact Information

Shanghai Consung Intelligent Technology Co.,Ltd.

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: consung@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: consung@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Products

Wet Glue Labeling Machine

|

Previous:

Next:

Model: CG-S100

Categories:

Cold Glue Labeling Machine

» Wet Glue Labeling Machine

»

Description:

Description:

1.It can adjust motor speed freely which equipped frequency converter, which also make sure cold glue labeling machine capacity.

2.Running strcuture use gear drive,small gap which make sure more smoothly in long running time, small nosiy and long lifetime.

3.High degree automation can fulfill gluing,label taking and labeling,and automatic photoelectric detection.

4.The machine processing precision is exquisite, the basic components are standard parts, convenient maintenance.

5.Photoelectric detection which achieve no bottle no labeling, to ensure that not waste label.

6.bottle feeding screw is from professional factory production and machine tool design which make sure bottle outfeeding smoothly.

7.We use PLC program control for the circuit, Relatively PLC has a greater extent to ensure stability for machine operation.

8.Paste slot adopt finest wear-resistant copper, proceed by lapping and stainless steel roller precision machining, glue used after machine checking, never leak glue, so as to ensure not wasting the wet glue.

9.Inverter used to adjust the speed, the motor can be freely adjusted, labeling capacity can be freely controlled.

10.Can be stand-alone operation, also can connect with the automatic production line, easy adjustment.

11.The whole machine adopt delicate precision machine processing technology, the basic components are all standard parts, easy maintenance.

Technical Parameters

1.It can adjust motor speed freely which equipped frequency converter, which also make sure cold glue labeling machine capacity.

2.Running strcuture use gear drive,small gap which make sure more smoothly in long running time, small nosiy and long lifetime.

3.High degree automation can fulfill gluing,label taking and labeling,and automatic photoelectric detection.

4.The machine processing precision is exquisite, the basic components are standard parts, convenient maintenance.

5.Photoelectric detection which achieve no bottle no labeling, to ensure that not waste label.

6.bottle feeding screw is from professional factory production and machine tool design which make sure bottle outfeeding smoothly.

7.We use PLC program control for the circuit, Relatively PLC has a greater extent to ensure stability for machine operation.

8.Paste slot adopt finest wear-resistant copper, proceed by lapping and stainless steel roller precision machining, glue used after machine checking, never leak glue, so as to ensure not wasting the wet glue.

9.Inverter used to adjust the speed, the motor can be freely adjusted, labeling capacity can be freely controlled.

10.Can be stand-alone operation, also can connect with the automatic production line, easy adjustment.

11.The whole machine adopt delicate precision machine processing technology, the basic components are all standard parts, easy maintenance.

| Round Bottle Diameter | 30-110mm |

| Label Dimension | L 30-300mm W30-150mm |

| Voltage | 380V 3Phrase 50HZ |

| Power | 1.2KW |

| Stability | can produce continuous 24hours |

| Air Consumption | 4-6kgs*18liter |

| Net Weight | abt 550KG |

Related Product

Hot Product

Didn't find what you are looking for? Send your inquiry.

Wet Glue Labeling Machine Manufacturer search on: Google, Yahoo, Msn

Wet Glue Labeling Machine Manufacturer search on: Google, Yahoo, Msn

Related Category:

Cold Glue Labeling Machine

» Wet Glue Labeling Machine

»

Keywords:

Opp Labeling Machine |

Hot Melt Labeling Machine |

Bopp Labeling Machine |

Sleeve Labeling Machine |

Adhesive Labeling Machine |

Round Bottle Labeling Machine |

Flat Labeling Machine |

Double Side Labeling Machine |

Horizontal Labeling Machine |

Sticker Labeling Machine |

Top Labeling Machine |

Wire Labeling Machine |

Cold Glue Labeling Machine |