Labeling Machine | OPP Labeling Machine | Sleeve Labeling Machine | Adhesive Labeling Machine | Sticker Labeling Machine.

You are here: Home » Products »

Hot Melt Labeling Machine

» Linear Type OPP Labeling Machine

» Linear Hot Melt OPP Labeling Machine

Products Catagories

News & Events

-

How to use Germany Sausages ...

[2021/7/27 16:12:58]Adhesive sticker labeling machine can work for sausages food, pet food, plastic tube,oral bottle. ...

-

Received the payment of Duba...

[2021/7/22 11:37:56]The deposit payment of flat conveyor and lifting conveyor, conveyors can connect with filling machine, capping machine,labeling machine and packing m...

-

Dental cream teeth cream tub...

[2021/7/13 15:49:35]Sticker labeling machine work with cans tubes round bottles....

-

New model power cord cable w...

[2021/7/8 9:06:52]Full automatic manual flag labeling machine can paste stick labels on powder cord, electrical cable and wire....

-

Suction cap automatic feedin...

[2021/7/7 9:10:34]The O and U shape labels machine equipment production line from automatic feeding cap, stick labeling to collecting machine work for Medicine indus...

Contact Information

Shanghai Consung Intelligent Technology Co.,Ltd.

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: consung@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: consung@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Products

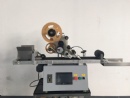

Linear Hot Melt OPP Labeling Machine

|

Previous:

Linear Hot Melt OPP Labeling Machine(High Speed)

Next:

Model: OPP-4P-L

Categories:

Hot Melt Labeling Machine

» Linear Type OPP Labeling Machine

»

Description:

1. It applies to a row of paste volume, the use of local means glue, glue consumption of small, low running costs.

2,Due to the design of high-precision processing requirements of strict and meticulous assembly, so that the stability of the machine running, and production capacity can reach 10,000 bottles / hour.

3. Marked station is the heart of the aircraft, designed to complete the standard trademarks station transmission constant tension; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; not send bottles marked function; glue function is not scale-free; bottle labeling before and after the replacement of the normal type;

4. The host used on home cam design to replace the bottle-type simple; nose tight card using pneumatic means to increase the convenience of the host.

5. The overall automation and control the use of PLC control, the servo system, the inverter system, temperature control systems and other needs with comprehensive control of the point.

6. Overload protection, security, protection of the design of complete, multi-point and fault protection device to ensure that the alarm sound and light man-machine safety.

7. Centralized lubrication system allows the operation of machinery lubrication components more simple, more normal, more to ensure that the machine life. The machine is simple and convenient maintenance.

8. A specially designed folder structure to ensure that trademarks are trademarks of trademarks has always been flexible in compacting the folder block.

9. Servo motor-driven traction trademark agencies, Photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10. Biaxial screw propeller institutions bottle into the bottle so that a more stable, high-speed into the bottle so much more smoothly.

11. Inflatable bottle of the local function is the quality of the container (grams) low, allowing users to reduce operating costs.

12. Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

13. Specifically the constant tension of the membrane material detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.

Technical Parameter

2,Due to the design of high-precision processing requirements of strict and meticulous assembly, so that the stability of the machine running, and production capacity can reach 10,000 bottles / hour.

3. Marked station is the heart of the aircraft, designed to complete the standard trademarks station transmission constant tension; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; not send bottles marked function; glue function is not scale-free; bottle labeling before and after the replacement of the normal type;

4. The host used on home cam design to replace the bottle-type simple; nose tight card using pneumatic means to increase the convenience of the host.

5. The overall automation and control the use of PLC control, the servo system, the inverter system, temperature control systems and other needs with comprehensive control of the point.

6. Overload protection, security, protection of the design of complete, multi-point and fault protection device to ensure that the alarm sound and light man-machine safety.

7. Centralized lubrication system allows the operation of machinery lubrication components more simple, more normal, more to ensure that the machine life. The machine is simple and convenient maintenance.

8. A specially designed folder structure to ensure that trademarks are trademarks of trademarks has always been flexible in compacting the folder block.

9. Servo motor-driven traction trademark agencies, Photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10. Biaxial screw propeller institutions bottle into the bottle so that a more stable, high-speed into the bottle so much more smoothly.

11. Inflatable bottle of the local function is the quality of the container (grams) low, allowing users to reduce operating costs.

12. Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

13. Specifically the constant tension of the membrane material detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.

Technical Parameter

| Capacity | 8000BPH(500ml) |

| Voltage | 380V,50HZ |

| Power | 8KW |

| Applicable Container | Round Bottle Dia.40-105mm,H 80-350mm |

| Applicable Label Size | L 125-325mm H20-190mm |

| Air Compression | 5-8Bar |

| Air Consumption | 0.2m3/min |

| Glue Consumption | 1KG glue for 10000pieces bottle(label height is 50mm) |

| Weight | 2500KG |

| Machine Size | 3150*1770*1800mm |

Related Product

Hot Product

Didn't find what you are looking for? Send your inquiry.

Linear Hot Melt OPP Labeling Machine Manufacturer search on: Google, Yahoo, Msn

Linear Hot Melt OPP Labeling Machine Manufacturer search on: Google, Yahoo, Msn

Related Category:

Hot Melt Labeling Machine

» Linear Type OPP Labeling Machine

»

Keywords:

Opp Labeling Machine |

Hot Melt Labeling Machine |

Bopp Labeling Machine |

Sleeve Labeling Machine |

Adhesive Labeling Machine |

Round Bottle Labeling Machine |

Flat Labeling Machine |

Double Side Labeling Machine |

Horizontal Labeling Machine |

Sticker Labeling Machine |

Top Labeling Machine |

Wire Labeling Machine |

Cold Glue Labeling Machine |