Labeling Machine | OPP Labeling Machine | Sleeve Labeling Machine | Adhesive Labeling Machine | Sticker Labeling Machine.

News Details

Rotary hot melt glue labeling machine

Author: April Date: 2014/9/10 20:04:51

Rotary hot melt glue labeling machine

Machine Configuration

1.Transport part of the bottle includes conveyor chains, spiral converyor, bottle inlet wheel, Roundabout, bottle outlet wheel . Main motor drives roundabout,roundabout drive other rotating.

2.Transport part of the label is also labeling station,including 1labeling plate,constant tension control and the operative part ,the label and labeling glue transfer part (with subscript suction drum,drum labeling Subscrip one suction drum,drum rotation label adopted by the main drive gear drive to achieve.The glue plastic parts , including pumps,glue and the glue circulatory system),labeling parts of servo traction.

Hot Melt Labeling Machine Working Principle

1.After getting through power, the machine can be operated by automatic ,manual or inching mode until there is no errors by self-inspection.

2.Bottles are carried into the machine by interscrew , in inlet star wheel place there is a transducer which used to determine whether giving the label by servol and gluing by cylinder .After confirming bottles arrive the certain position,servo motor starts to drive pull roll to transfer the first label,the cutter cuts the label and then is transferred to the gripper cylinder,when the cylinder runs to the place of gluing,the cylinder of gluing proceed to glue while bottle rotates on the bottle table.When label on the gripper cylinder meet the bottle which rotating on the bottle table,the vacuum pump stop to work to free the label,the label is sicked on the bottle with glue. So, finishing the process of labeling. Then the bottle is carried to the pressing label device by bottle table, and lead out on the conyor by outlet screw to the next process of packing.

3.It’s rated speed is 20000 bottles/hour,Trademark cutting accuracy can be achieved deviation ≤±1mm(marked with encoder station,sent to follow the label servo motor encoder signals and color of the dual role of the sensor,in accordance with the actual deviation of the subject color to complete the position servo compensation). At the same time, according to the different requirements of customers, requirements apply to a wide range of specifications trademarks and speed; production speed can be step less speed regulation. Bottle-type according to the customer request the actual situation, to send labeler marking drum speed and the bottle diameter composite wire speed (revolution roundabout line speed and line speed of rotation of the bottle and vector) in the high, medium and low speed, the large and small , the same bottle completely to ensure that labeling effects. Standard delivery requires low-speed servo motor to achieve non-standard bottles send, no glue bottle does not function, to ensure that intermittent access to the machine when the bottle marked points can be marked smooth and send in to send to switch between standard, the accuracy of the entire normal standard.

4.If the machine run-time anomalies, automatic alarm control system, according to the police the location of the machine will automatically stop or slow down immediately, in case of emergency, you can through the stop button to stop the machine man-made emergencies. Stop through the safety circuit to achieve, you can guarantee a higher level of security. Dynamic mode of operation a bit machines, in the mode to move to be completed automatically under the action of all, the machine for debugging.

5.Man-machine interface can show the actual state of machine, production, hot melt adhesive temperature, suction temperature standard drum messages, in the failure and how to deal with all kinds of alarm message at a glance, a user-friendly in the face of failure messages quickly in accordance with troubleshooting, friendly interface. In bids for debugging, or can manually start or restart the machine to move, easy to operate.

6.Electrical machine are as follows: the main motor, to increase the motor, vacuum pumps, plastic pumps, send standard servo motors, servo motor turning the bottle

Perfect Hot Melt Labeling Machine Structure Design

1.Due to the design of high-precision processing requirements of strict and meticulous assembly, so that the stability of the machine running, and production capacity can maximum reach to 24000 bottles per hour.

2.Rotary design, compact structure, beautiful shape, material specification.

3.It marked station is the heart of the standard station designed to be completed trademarks constant tension transmission; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; non-standard features send a bottle; function is not scale-free coating; bottle labeling before and after the replacement of the normal type;

4.Roll fed labeling machine host use rear-mounted cam design to replace simple bottle type; nose tight card use pneumatic means to increase the convenience of the host.

5.Automation and control overall control of the use of PLC to servo system, inverter system, and temperature control system and other requirements with comprehensive control of the point.

6.Overload protection, security, protection of complete design, multi-point and fault protection device to ensure the alarm sound and light man-machine safety.

7.Centralized lubrication system allows the operation of machinery lubrication components to be more simple, more normal, to ensure machine life. simple machine and convenient maintenance.

8.Specially designed folder trademark finger is always to ensure that trademarks are trademarks of elastic compression in the folder block.

9.Servo motor-driven traction trademark agencies, photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10.Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

11.Specialized membrane material constant tension detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.

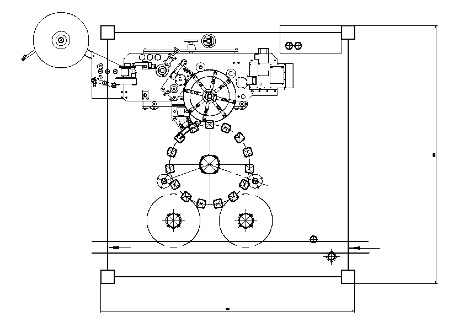

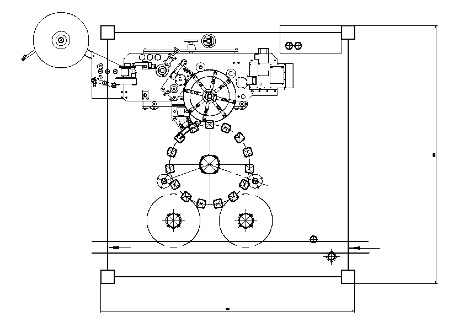

Machine Picture&drawing

If you have interests about our rotary opp hot melt glue labeling machine, pls feel free to contact us! Send email to consung@consung.com.cn

Machine Configuration

1.Transport part of the bottle includes conveyor chains, spiral converyor, bottle inlet wheel, Roundabout, bottle outlet wheel . Main motor drives roundabout,roundabout drive other rotating.

2.Transport part of the label is also labeling station,including 1labeling plate,constant tension control and the operative part ,the label and labeling glue transfer part (with subscript suction drum,drum labeling Subscrip one suction drum,drum rotation label adopted by the main drive gear drive to achieve.The glue plastic parts , including pumps,glue and the glue circulatory system),labeling parts of servo traction.

Hot Melt Labeling Machine Working Principle

1.After getting through power, the machine can be operated by automatic ,manual or inching mode until there is no errors by self-inspection.

2.Bottles are carried into the machine by interscrew , in inlet star wheel place there is a transducer which used to determine whether giving the label by servol and gluing by cylinder .After confirming bottles arrive the certain position,servo motor starts to drive pull roll to transfer the first label,the cutter cuts the label and then is transferred to the gripper cylinder,when the cylinder runs to the place of gluing,the cylinder of gluing proceed to glue while bottle rotates on the bottle table.When label on the gripper cylinder meet the bottle which rotating on the bottle table,the vacuum pump stop to work to free the label,the label is sicked on the bottle with glue. So, finishing the process of labeling. Then the bottle is carried to the pressing label device by bottle table, and lead out on the conyor by outlet screw to the next process of packing.

3.It’s rated speed is 20000 bottles/hour,Trademark cutting accuracy can be achieved deviation ≤±1mm(marked with encoder station,sent to follow the label servo motor encoder signals and color of the dual role of the sensor,in accordance with the actual deviation of the subject color to complete the position servo compensation). At the same time, according to the different requirements of customers, requirements apply to a wide range of specifications trademarks and speed; production speed can be step less speed regulation. Bottle-type according to the customer request the actual situation, to send labeler marking drum speed and the bottle diameter composite wire speed (revolution roundabout line speed and line speed of rotation of the bottle and vector) in the high, medium and low speed, the large and small , the same bottle completely to ensure that labeling effects. Standard delivery requires low-speed servo motor to achieve non-standard bottles send, no glue bottle does not function, to ensure that intermittent access to the machine when the bottle marked points can be marked smooth and send in to send to switch between standard, the accuracy of the entire normal standard.

4.If the machine run-time anomalies, automatic alarm control system, according to the police the location of the machine will automatically stop or slow down immediately, in case of emergency, you can through the stop button to stop the machine man-made emergencies. Stop through the safety circuit to achieve, you can guarantee a higher level of security. Dynamic mode of operation a bit machines, in the mode to move to be completed automatically under the action of all, the machine for debugging.

5.Man-machine interface can show the actual state of machine, production, hot melt adhesive temperature, suction temperature standard drum messages, in the failure and how to deal with all kinds of alarm message at a glance, a user-friendly in the face of failure messages quickly in accordance with troubleshooting, friendly interface. In bids for debugging, or can manually start or restart the machine to move, easy to operate.

6.Electrical machine are as follows: the main motor, to increase the motor, vacuum pumps, plastic pumps, send standard servo motors, servo motor turning the bottle

Perfect Hot Melt Labeling Machine Structure Design

1.Due to the design of high-precision processing requirements of strict and meticulous assembly, so that the stability of the machine running, and production capacity can maximum reach to 24000 bottles per hour.

2.Rotary design, compact structure, beautiful shape, material specification.

3.It marked station is the heart of the standard station designed to be completed trademarks constant tension transmission; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; non-standard features send a bottle; function is not scale-free coating; bottle labeling before and after the replacement of the normal type;

4.Roll fed labeling machine host use rear-mounted cam design to replace simple bottle type; nose tight card use pneumatic means to increase the convenience of the host.

5.Automation and control overall control of the use of PLC to servo system, inverter system, and temperature control system and other requirements with comprehensive control of the point.

6.Overload protection, security, protection of complete design, multi-point and fault protection device to ensure the alarm sound and light man-machine safety.

7.Centralized lubrication system allows the operation of machinery lubrication components to be more simple, more normal, to ensure machine life. simple machine and convenient maintenance.

8.Specially designed folder trademark finger is always to ensure that trademarks are trademarks of elastic compression in the folder block.

9.Servo motor-driven traction trademark agencies, photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10.Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

11.Specialized membrane material constant tension detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.

Machine Picture&drawing

If you have interests about our rotary opp hot melt glue labeling machine, pls feel free to contact us! Send email to consung@consung.com.cn

Products Catagories

News & Events

-

How to use Germany Sausages ...

[2021/7/27 16:12:58]Adhesive sticker labeling machine can work for sausages food, pet food, plastic tube,oral bottle. ...

-

Received the payment of Duba...

[2021/7/22 11:37:56]The deposit payment of flat conveyor and lifting conveyor, conveyors can connect with filling machine, capping machine,labeling machine and packing m...

-

Dental cream teeth cream tub...

[2021/7/13 15:49:35]Sticker labeling machine work with cans tubes round bottles....

-

New model power cord cable w...

[2021/7/8 9:06:52]Full automatic manual flag labeling machine can paste stick labels on powder cord, electrical cable and wire....

-

Suction cap automatic feedin...

[2021/7/7 9:10:34]The O and U shape labels machine equipment production line from automatic feeding cap, stick labeling to collecting machine work for Medicine indus...

Contact Information

Shanghai Consung Intelligent Technology Co.,Ltd.

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: marketing@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Add: Building B, No.161, Zhenye Road,Dongjing Town, Songjiang District,Shanghai

Tel.: 0086-21-67658975

Fax: 0086-21-67658975

Email: marketing@consung.com.cn

Skype: consungmachinery

Web: http://www.consung-labeling.com

Keywords:

Opp Labeling Machine |

Hot Melt Labeling Machine |

Bopp Labeling Machine |

Sleeve Labeling Machine |

Adhesive Labeling Machine |

Round Bottle Labeling Machine |

Flat Labeling Machine |

Double Side Labeling Machine |

Horizontal Labeling Machine |

Sticker Labeling Machine |

Top Labeling Machine |

Wire Labeling Machine |

Cold Glue Labeling Machine |